Steel Grades

Cold-worked Steel reinforcements and mechanical specifications

Our Steel Grades

Scheibinox is a manufacturer of cold-worked stainless steel. Our grades 1.4571, 1.4362 and Inoxripp4486 (1.4482) are meet the strict qualifications by the German Certification Institute (DIBt) for the domestic market. We also develop custom grades for you as needed or specified - just request a quote.

Inoxripp4486

Scheibinox Inoxripp4486 is a new lean duplex with national technical approval (Z-1.4-261). It is available in diameters between 6 and 32 mm.

1.4362

Scheibinox 1.4362 is a lean duplex with national technical approval (Z-1.4-228). It is available in diameters between 6 and 32 mm.

1.4571

Scheibinox 1.4362 is an austenite steel grade with national technical approval (Z-1.4-50). It is available in diameters between 6 and 14 mm.

Availability

We produce our own cold-worked stainless steel at our site in Kamp-Lintfort (Western Germany). We usally keep larger quantities of our steel grades in standard dimensions in stock - available at all times - so we can quickly react to your specific needs. On construction sites, an urgent demand for additional steel reinforcement is very common, so don't hesitate to ask. In the table you will find a quick overview of our availabilities.

Note: Diameters 3-5 mm and 25-32 mm don't have the German DIBt certificate. Diameters 16- 2 mm are only available as rebars.

| D | Inoxripp4486 | 1.4362 | 1.4571 |

| 3 mm | --- | on request | --- |

| 4 mm | --- | always available | --- |

| 5 mm | always available | on request | --- |

| 6 - 12 mm | always available | always available | always available |

| 14 mm | always available | --- | always available |

| 16 - 20 mm | always available | on request | --- |

| 25 - 32 mm | always available | on request | --- |

Interesting Facts

In Germany, the production and application of stainless steel reinforcement is regulated by the technical authority and approval body Deutsches Institut für Bautechnik (DIBt), which grants national technical approvals to ensure the safety of construction products. Obtaining a national technical approval requires extensive testing of the respective stainless steel grade such as tensile test series, fatique tests and corrosion tests. Additionally owner of technical approval have to continuously verify that the technical properties of their products comply with the requirements of the national technical approval.

In general, German construction projects need the steel to be approved by the DIBt. Manufacturers need to have the according technical approvals so that construction companies can install the steel without reservation. Therefore it is advisable to check whether a certification is necessary and existing - otherwise in case of not certified steel German construction sites might even get shut down altogether.

Despite this being an all German certificate, the German national technical approval covers most of the requirements of national regulations for other European countries. You can read more on the subject on the relevant German content of the site.

"Stainless Steel" is a category of all sorts of steel that have a high portion of chromium - specifically more than 10.5%. This builds a passive chromium oxide layer makes the steel more corrosion resistant. This layer is a continuous skin on the surface that will re-passivate on penetration immediately, keeping it corrosion-resistant at all times. This makes it entirely different from a zinc-coating. The higher the chromium portion, the more stable the chromium oxide layer. Alloy components like nitrogen also have a positive effect on corrosion resitance.

Depending on the chemical composition of these stainless steel grades different degrees of corrosion resistances are the result. The CRC (corrosion resistancy class) is the metric defining this property, with class I being the lowest (example: 1.4003) and V being the highest resitancy (example: 1.4547). In the German industry norm (DIN EN 1993) most steel grades are classified by CRC. For steel grades not covered by this norm the PREN effective sum delivers a good way to have an idea of the CRC equivalent of this sort of steel:

PREN = 1 x %Cr + 3,3 x %Mo + 16 x %N

%Cr is the chromium content, %Mo the molybdenum content and %N the nitrogen content of the steel grade. Higher values mean greater corrosion resistance.

Based on the exposure class of an application area as well as the planned concrete cover, the corrosion resistance classes can be used to determine suitable materials for a construction project.

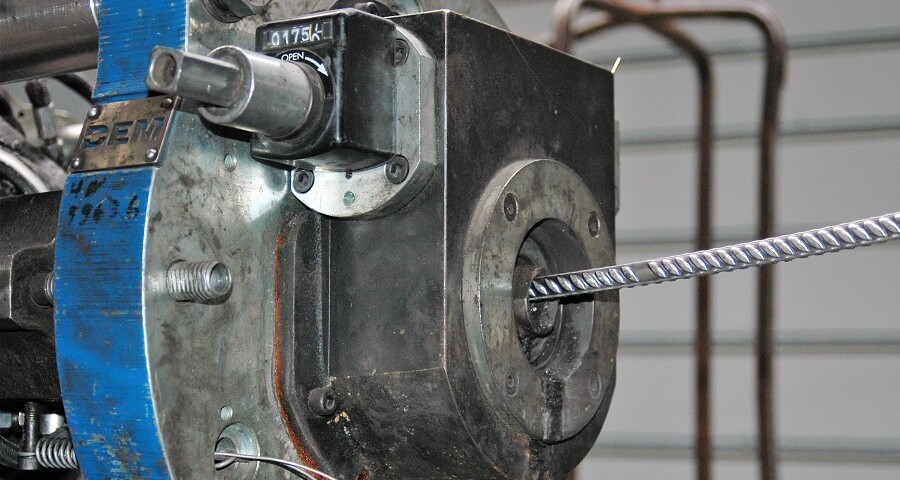

Cold-working and hot-rolling are two different manufacturing processes for stainless steel reinforcement. In hot-rolling, the wire is produced at a high temperature above the recrystallization temperature and thereby acquires its mechanical properties as well as its ribbed shape. In cold-working, hot-rolled wire rod is drawn through cassettes mounted with special rolls in a further manufacturing step, where plastic deformation presses the ribs onto the steel.

Cold-worked and hot-rolled reinforcing steel differ essentially in hardness as well as ductility. Stainless steel produced by cold-working wire rod is significantly harder than hot-rolled steel grades. This results in higher strengths (for duplex steels at least 800 N/mm² compared with 550 N/mm²) and higher yield strengths (for duplex steels at least 700 N/mm² compared with 500 N/mm²). On the other hand, hot-rolled steel is generally more ductile and has a higher toughness, usually ductility class B.

Newly developed steel grades however achieve both high strength and yield strength while ensuring ductility through cold-working (such as our Inoxripp4486). These mechanical properties allow for new possibilites for construction designers and architects, such as reducing the steel cross-section due to higher strength values, reducing total weight and cost at the same time.

The designations B500B NR and B700B NR are German abbreviations for stainless steel grades, which have their origin in conventional structural steels. In the abbreviation, the first B stands for reinforcing steel, 500/700 for the yield strength (in N/mm²), the second B for the ductility class (alternatively A/C) and NR for "nicht rostend" (German for "non-corrosive"). Our Inoxripp4486 is classified as B700B NR, our 1.4571 as B500B NR and our 1.4362 as B500A NR.

In Germany, a yield strength of 500 N/mm² is normally used for design and dimensioning in accordance with Eurocode 2 (DIN EN 1992-1-1). Design with higher yield strengths usually needs approval on a case-by-case basis. In addition, it is possible to include the design and dimensioning with higher yield strengths in the technical approval of a reinforcing steel product.

We have taken this route with our Inoxripp4486 and have had the requirements for the design and calculation with a yield strength of 700 N/mm² checked and assessed for the aspects of the ultimate limit state (LCS) and the serviceability limit state (SST) defined in Eurocode 2. As a result, our Inoxripp4486 was classified as B700B NR and the building authority approval was extended accordingly.

- Bending with longitudinal force

- Shear force without shear reinforcement

- Bar models

- Anchorages, overlaps and bends

- Crack widths