Why choose Scheibinox

Maintaining our quality standards

Quality that you can trust

Meeting customer requirements is our top priority and we see outstanding quality as a decisive factor in our success in the face of national and international competition.

Quality therefore plays a central role in all our company processes - from the preparation of quotations and orders, through production and materials testing, to shipping and invoicing. We attach particular importance to ensuring that our products fully meet the high requirements of our customers and building regulations.

We have this understanding of quality confirmed by independent bodies through corresponding certificates and are subject to constant external monitoring, particularly in the area of product quality.

In a nutshell

- Official Technical Approval of German Building Authority "Deutsches Institut für Bautechnik (DIBt)"

- Certified Management System according to ISO 9001-2015

- No contact-rust through strict separation from common steel materials

- Inhouse Quality Control and Assurance

- Continuous supervision by the German office for material testing (Materialprüfungsamt NRW)

Management System accordng to ISO 9001-2015

The quality management standard ISO 9001 is a nationally and internationally recognized and the most widely used standard in quality management. It helps organizations to meet customer requirements, improve the quality of their products or services and increase customer satisfaction.

Our management system is certified according to the ISO 9001-2015 standard. The certificate - issued by DEKRA as an independent certification body - confirms that our organizational and operational structure is documented, traceable and reproducible and is subject to a continuous improvement process. Our processes are aligned with the requirements of our customers with the aim of optimally fulfilling them.

| # | Dokument | Download |

|---|---|---|

| 1 | Download (430.09 KB) |

Prevention of Contamination

Although stainless reinforcing steel is protected against corrosion by a chromium oxide layer, improper processing and handling (e.g. contact with conventional steel) can result in rust particles reaching the surface and contaminating it.

To prevent this, we guarantee that our stainless steel reinforcement does not come into contact with conventional steel at any time during production and therefore no contact rust is created. To achieve this, we have equipped our machinery accordingly: Drawing machine linings, drawing disks, wire pullers, decoilers, etc. are made of stainless steel or are coated with stainless steel in areas subject to low stress. This also applies to our transport equipment, unless plastic or hemp ropes are used.

Materials testing and production control according to DIN 488-6

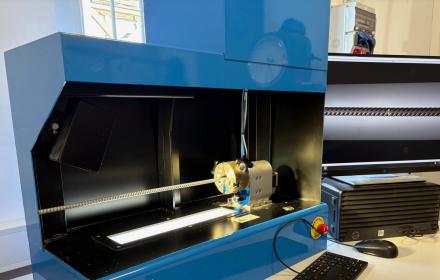

As a manufacturing plant for cold-worked stainless steel, we have a factory production control system in accordance with DIN 488-6 (German industry standard) for the continuous monitoring of our products. In this way, we ensure that our products comply with the provisions of the building authority approvals of the German Institute for Building Technology (DIBt).

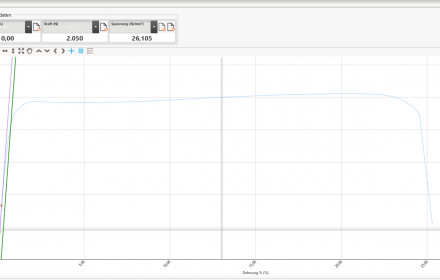

Tensile tests to determine the mechanical properties of our stainless steel reinforcement are carried out regularly in our test lab in accordance with DIN 488-6. The test results of each material batch and product type are documented and enclosed with our deliveries in a 3.1 test certificate.

Furthermore, the results are stored and statistically evaluated to ensure the long-term quality level of our products.

Independent Monitoring and Quality Control

In addition to our factory production control, we are externally monitored by the "Materialprüfungsamt" (MPA) NRW, based in Dortmund, Germany. The MPA is an independent government branch in charge of building inspectorate approvals.

There are two steps being monitored

- Confirmation of our test results by carrying out their our own tensile tests.

- Further tests are carried out on additional mechanical properties of our stainless steel reinforcement, such as fatigue tests

Compliance with the provisions of our building authority approvals will be confirmed to us by the MMPA NRW through corresponding certificates of compliance. In addition, our building inspectorate approvals are recertified by the DIBt every 5 years.

Our certificates for Germany

These are mostly irrelevant outside Germany, since they are only certifications, but considering the high standards that the German construction industry has, they are worth mentioning. To cut a long story short: Take a look at German architecture and housing. There is nothing like it in any other country - and this is part of the reason.